ENGINEERINGPRODUCTION

USING MODERN TECHNOLOGIES

FOR PRECISE RESULTS

Thanks to our technologies, we provide customers with comprehensive services for various industry sectors.

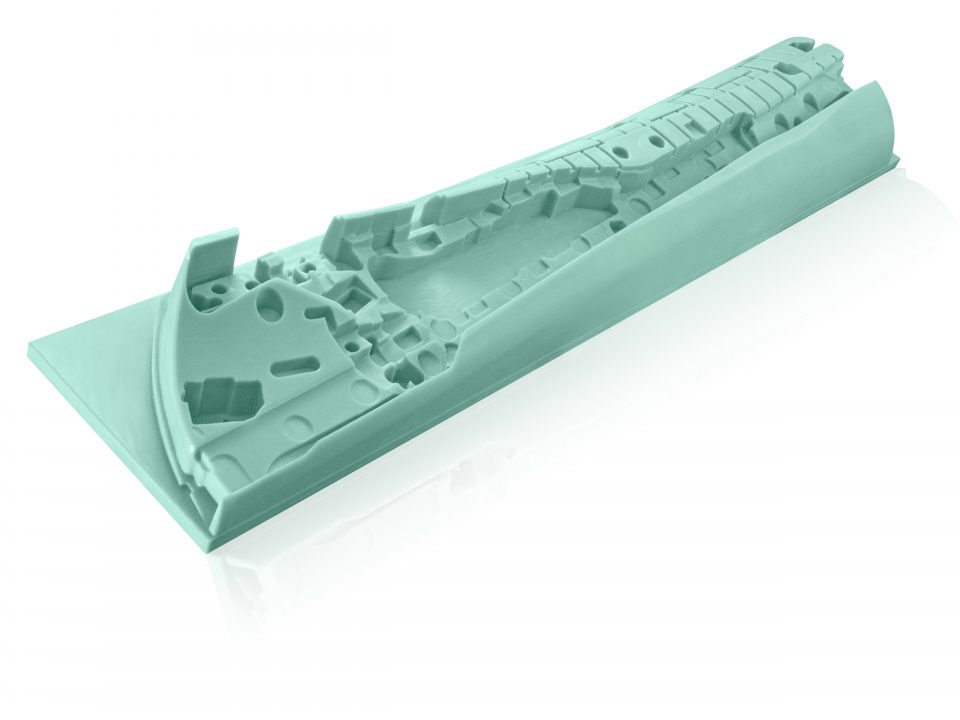

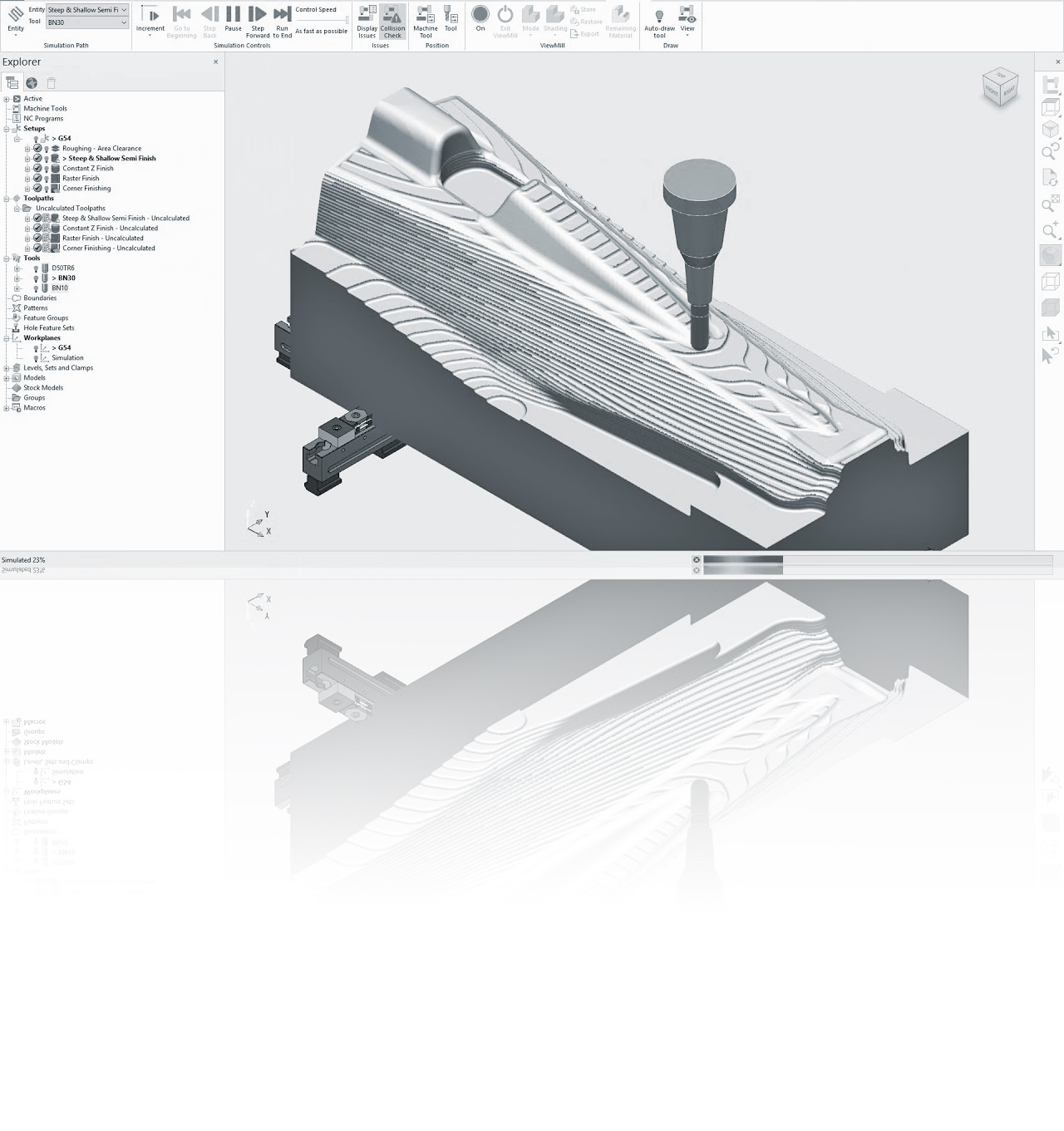

TECHNICALPRODUCTIONPREPARATION

CAD: AUTODESK INVENTOR, AUTOCAD CAM: POWERMIL, FUSION 360, EDGECAM

Our team comprises progressive and proven technologists who work with modern CAD/CAM software. We provide 3D product models, exploded-view assembly drawings, draft production documentation, preparation of accompanying documentation, and technical procedures creation, including CNC centre programming.

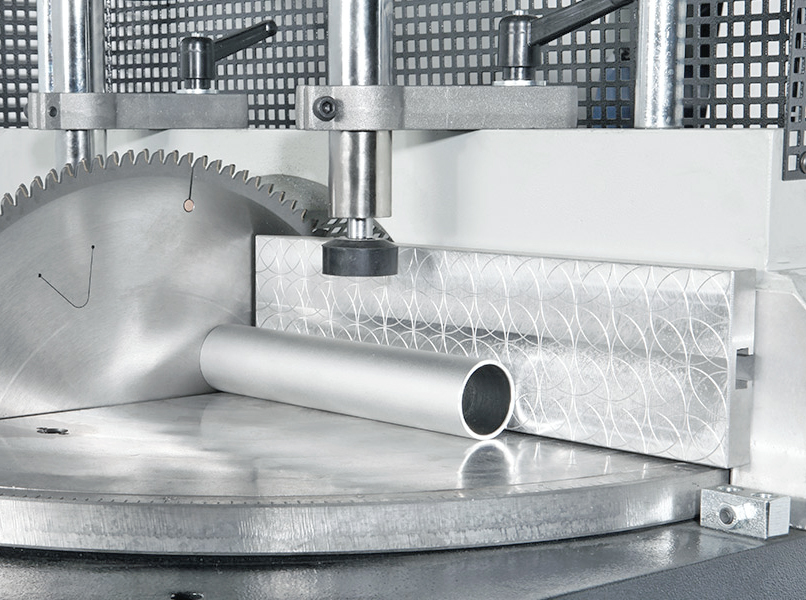

MATERIALSEPARATION

We cut materials using circular saws and band saws in our manufacturing facility. We provide material separation with formatting saws, water jets, lasers and plasma technology in cooperation with our partners.

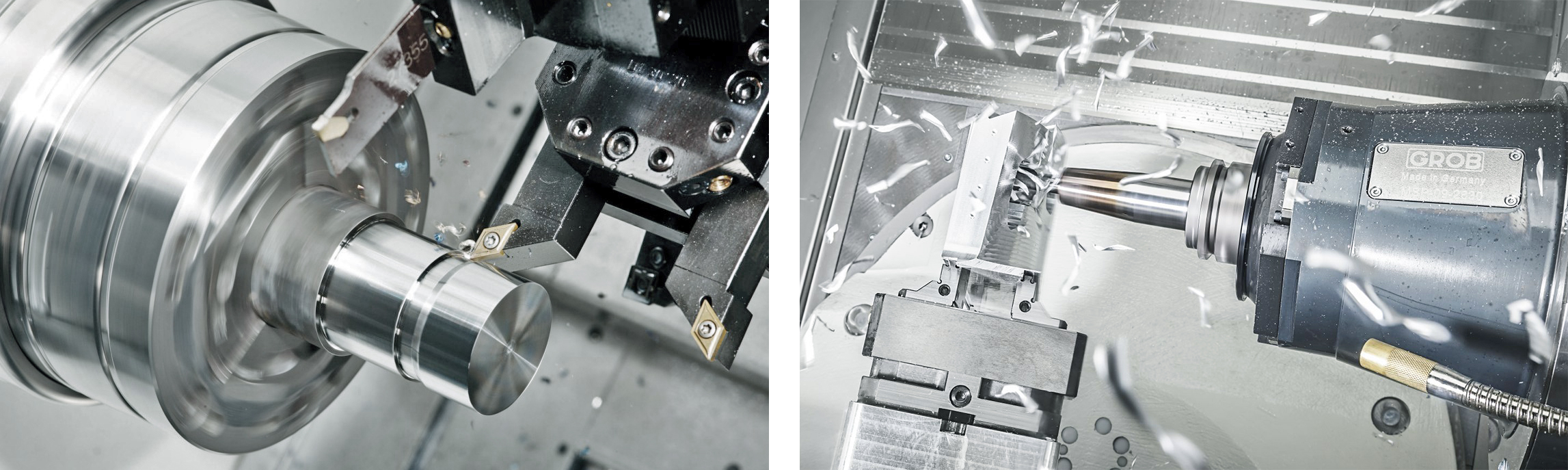

CHIPMACHINING

Chip machining is the primary area of focus of our production activities. Thanks to the modernisation of our tooling capacities, we can produce precise components in extraordinarily complex shapes. Our machines can deliver precision down to 0.006 mm and achieve a roughness of Ra 0.4.

MAXIMUM PRODUCT DIMENSIONS: 3-AXIS MILLING X 1800 x Y 700 x Z 700 mm 5-AXIS MILLING Ø 800 mm CNC TURNING Ø 680 mm

HEATTREATMENTAND SURFACEFINISHES

FINAL SURFACE FINISHING OF PRODUCTS IS A GIVEN WITH METAL CHIP MACHINING

We provide a complete product service in terms of surface finishes and heat treatment in cooperation with our long-term partners.

WELDING

OUR COMPANY

IS CERTIFIED UNDER

ČSN EN15085-2, LEVEL CL2

ČSN EN ISO 3834-2

STN EN 1090-2:2019

Welding of all types of steels using MIG/MAG and TIG/WIG methods by certified welders.

ASSEMBLY

OUR WORKSTATIONS ARE EQUIPPED WITH MODERN EQUIPMENT FOR MECHANICAL, ELECTRICAL, PNEUMATIC AND HYDRAULIC ASSEMBLY.

We have numerous assembly workstations where we conduct a broad range of assembly work.

QUALITYCONTROL

OUR COMPANY IS CERTIFIED UNDER THE ISO 9001:2015 QUALITY MANAGEMENT STANDARD.

The quality control department is responsible for assuring internal supplier and customer quality. The company has a metrology laboratory equipped with modern measurement devices from Carl-Zeiss for 3D measurements and MAHR for contour graphs.

We have experience with PPAP processes, Control plans and G8D reports.

OURLATESTPROJECTS