ABOUT US

CHALLENGES HOLD THE POTENTIAL FOR GROWTH ON MANY LEVELS.

We focus on custom piece production and serial production for various industries and engineering sectors, including the final assembly of products. Besides that we develop single-purpose equipment for different sectors and help enterprises automate their production processes. We gained extensive experience in deliveries for the electronics, automotive, engineering and wood processing industries.

Supratek’s roots date back to 2005 when its founder Martin Sučák decided to go into the engineering production business. Experience gained through years of work in this sector combined with a dynamic and creative team enabled the company to grow quickly and create a stable position.

“The driving force behind the company is the desire to take on new challenges, the joy from successfully completing projects, and to continuously improve in engineering. We are convinced that this approach will continue to lead us along the road to success.”

Best Regards Martin Sučák

COMPANYHISTORY

2005

ORIGINS OF SUPRATEK

The first trade license under which we commenced our activities was registered in 2005. At the beginning, most of our capacities were utilised to prepare fixtures for the electronics industry, along with metal tools production.

2008

RELOCATION OF OPERATIONS

and transformation into a limited liability company Our manufacturing facility and offices moved into larger and more suitable premises at the site of the former TAZ Trnava plant. The company also transformed into a limited liability company.

2010

ISO 9001:2008 CERTIFICATION

After acclimatisation and stabilisation of the company’s operations in the new facility, the next phase of internal development followed, which included successful completion of the ISO 9001:2008 certification process

2012

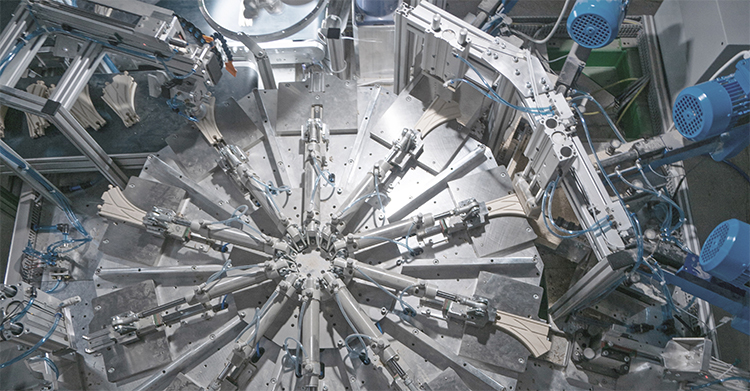

FIRST SUCCESSFUL AUTOMATION PROJECTS

With the successful completion of our first automation products, we became a reliable partner for our customers in this sector.

2013

COATINGS FOR COMPOSITE PARTS

2014

NEW MANUFACTURING FACILITY

We managed to find new space at our existing facility suitable for renovation and subsequent expansion of our manufacturing operations.

2015

FIRST 5-AXIS MACHINING CENTRE

After persistent effort, we finally met the conditions for a grant under the EU Competitiveness and Human Resources operational programme, which helped us equip our new facility with a cutting-edge 5-axis machining centre sourced from the renowned manufacturer GROB.

2016

WELDING CERTIFICATION

ČSN EN ISO 3834-2-2006 ČSN EN 15085-2-2008-CL2

2017

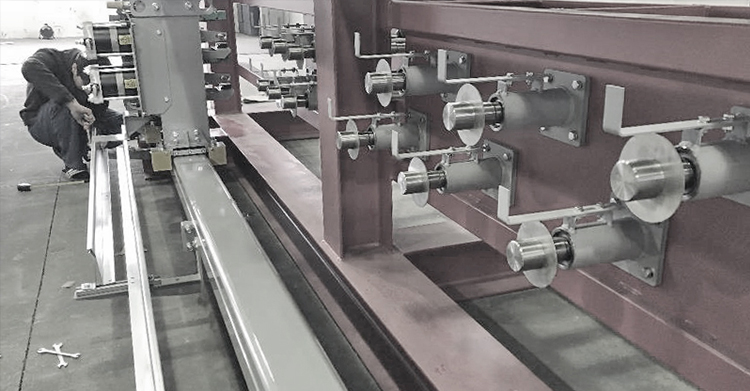

ENTRY INTO THE HEAVY ENGINEERING INDUSTRY

The next natural step in our company’s advancement was the decision to take on a heavy engineering project.

2018

INFORMATION SYSTEM DEPLOYMENT

The company’s growth in recent years necessitated the deployment of a professional production planning system. Its implementation streamlined process management and planning across the entire company.

2019

EMPLOYEE ACCOMMODATION

Construction of a facility to accommodate up to 40 persons.

2020

PURCHASE OF NEW EQUIPMENT DMG MORI, CONTURA G2

To cover demand for our products, we expanded our production capacities with a new DMG MORI 5-axis machining centre. We also equipped our quality laboratory with Carl-Zeiss and Contura G2 measurement devices.